We Manufacture “W and X” Series “DCDMA-BS” casing tubes from SAE 1541 superior quality cold drawn seamless steel tubes as per BS 4019-4:1993 and ISO 3551-2:1992. Casing tubes of all sizes both flush jointed and flush coupled are machined with utmost precision to maintain interchangeability. Smooth bore is maintained to allow the drill rods, barrels and bits to pass through unhindered

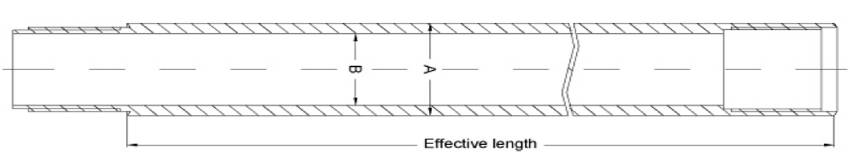

"W" Series Casing Tubes are flush jointed with integral male thread at one end and box thread at the other end.

These are heavy duty type with more wall thickness and used in rugged drilling conditions and with stand high torque.

Sizes and Specifications

| Size | Casing O.D. A (mm) |

Casing O.D. B (mm) |

Threads per inch (TPI) |

Standard Effective Length |

Threading |

|---|---|---|---|---|---|

| SW | 168.5 | 154.0 | 5 | 3 metres | Right Hand |

| PW | 140.0 | 125.0 | 5 | 3 metres | Right Hand |

| HW | 114.3 | 101.6 | 5 | 3 metres | Right Hand |

| NW | 89.0 | 76.4 | 8 | 3 metres | Right Hand |

| BW | 73.1 | 60.4 | 8 | 3 metres | Right Hand |

| AW | 57.3 | 48.5 | 8 | 3 metres | Right Hand |

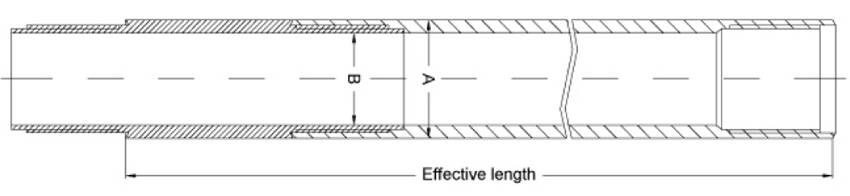

"X" Series Casing Tubes are flush coupled. Casings will have a box thread at both ends and joined with the help of a Pin-Pin coupling.

When damaged, the couplings can be replaced independently without having the necessity to buy entire casing.

Sizes and Specifications

| Size | Casing O.D. A (mm) |

Casing O.D. B (mm) |

Threads per inch (TPI) |

Standard Effective Length |

Threading |

|---|---|---|---|---|---|

| PX | 140.0 | 125.0 | 5 | 3 metres | Right Hand |

| HX | 114.5 | 100.1 | 5 | 3 metres | Right Hand |

| NX | 89.0 | 76.4 | 8 | 3 metres | Right Hand |

| BX | 73.1 | 60.4 | 8 | 3 metres | Right Hand |

| AX | 57.3 | 48.5 | 8 | 3 metres | Right Hand |

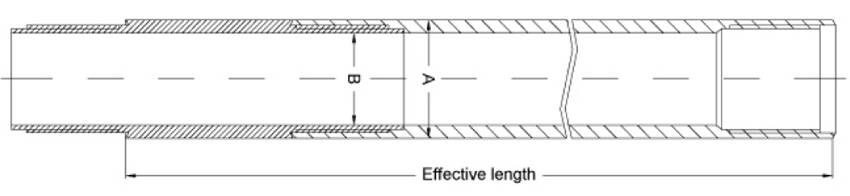

MFI Metric Casing Tubes are manufactured from superior quality cold drawn seamless steel tubes.

These are flush jointed with integral male thread at one end and box thread at the other end Metric casing tubes are light weight because of thin wall and have a wider size range to suit all applications.

Sizes and Specifications

| Size | Tube O.D. A (mm) |

Tube O.D. B (mm) |

Threads per inch (TPI) |

Standard Effective Length |

|---|---|---|---|---|

| 146 (143/134) | 143.3 | 133.3 | 4 | 3 |

| 131 (128/119) | 128.4 | 118.4 | 4 | 3 |

| 116 (113/104) | 113.4 | 103.4 | 4 | 3 |

| 101 (98/89) | 98.4 | 88.4 | 4 | 3 |

| 86 (84/77) | 84.4 | 77.5 | 4 | 3 |

| 76 (74/67) | 74.4 | 67.5 | 4 | 3 |

| 66 (64/57) | 64.4 | 57.5 | 4 | 3 |

| 56 (54/47) | 54.3 | 47.4 | 4 | 3 |

| 46 (44/37) | 44.3 | 37.4 | 4 | 3 |

Metal forging Industries is a leading manufacturers of Friction welding Hardened Drill Rods, DTH Hammers, DTH Bits, Sub Adaptors, Core Drilling Rods, Steel Forgings & many other drilling related consumables as well.

Metal Forging Industries

Plot No. 52/A, Sector-II, Lane-IV, Phase-II, IDA Cherlapally, Hyderabad, Telangana, India – 500051.

+91 93962 33303

+91 73306 63304

info@metalforgingsindia.in

marketing@metalforgingsindia.in

sales@metalforgingsindia.in